Types of Clamps to Know

In maintenance, repair, and operations (MRO) environments, clamps generally fall into two categories:

- Hose Clamps: Designed to secure fluid lines and prevent leaks in engines, plumbing, and hydraulic systems.

- Rubber Clamps or Insulated Clamps (Including Cushioned P-Clamps/Nylon Clamps): Built to fasten hoses, pipes, or cables while protecting them from abrasion and vibration.

Knowing when to use each type is important too. For example: A worm-gear hose clamp might be the right fit for a cooling system, while a cushioned P-clamp (nylon clamp) is better suited for holding a wiring harness along a vehicle chassis.

At Ram Products, we carry a full range of Hose Clamps, Rubber Clamps, Insulated Clamps, and P-Clamps (Nylon Clamps). This guide will walk you through the different types, how to choose the right one, and expert tips to get the best performance in your applications.

From the Ram Products Experts

“When choosing clamps, think about what you’re trying to do first. Need to seal a fluid line? Reach for a hose clamp. If you’re just securing or routing a hose or cable, an insulated or cushioned clamp will protect it from wear and vibration.”

Hose Clamps: Types & Applications

Hose clamps are one of the most common fasteners in maintenance and industrial settings, but not all hose clamps are created equal.

Choosing the right type ensures a secure fit and long-lasting performance, whether you’re working on engines, plumbing, or hydraulic systems.

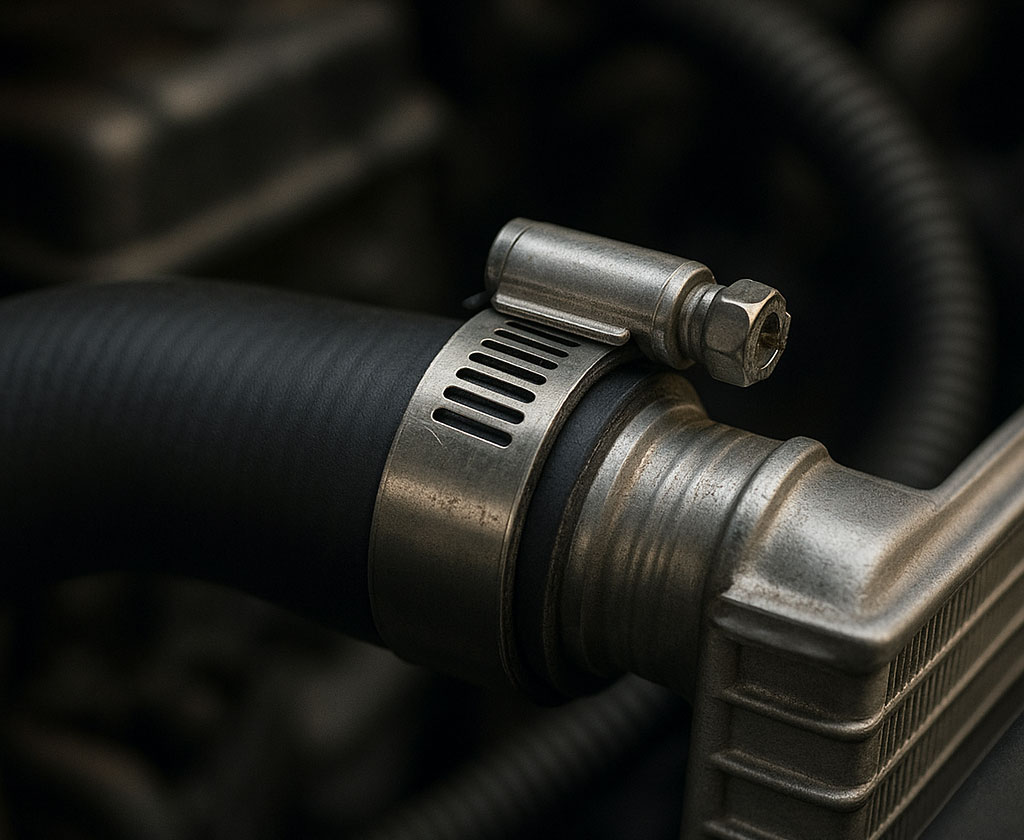

- Worm Gear Clamps: Adjustable and versatile, these are ideal for most automotive and machinery hoses. A slotted band tightens via a screw, making them simple to install and reuse.

- T-Bolt Clamps: Heavy-duty clamps designed for high-pressure applications, like turbocharger lines. They provide consistent clamping force and resist loosening under vibration.

- Ear Clamps: Sometimes called “Oetiker clamps,” these are typically one-time-use and provide a tamper-resistant, permanent seal. They’re commonly used in fuel lines and cooling systems.

- Spring Clamps: Lightweight, spring-steel clamps that maintain constant pressure as hoses expand and contract with heat cycles. Often used in automotive cooling and radiator lines.

Where They’re Used

Hose clamps secure fluid-carrying hoses in engines, cooling systems, hydraulic systems, and plumbing setups. The right clamp prevents leaks, protects hoses from slipping off fittings, and ensures equipment runs reliably.

From the Ram Products Experts

“Many people over-tighten worm gear clamps, thinking more torque means a better seal. Too much force can cut into the hose and cause leaks down the line.”

Check out Ram Products’ Hose Clamps category for a full range of sizes and styles.

Rubber Clamps, Insulated & P-Clamps (Cushioned Clamps)

While hose clamps are primarily about sealing fluid lines, rubber-coated, insulated, and cushioned P-clamps (nylon clamps) are designed to secure and protect hoses, cables, and wiring from wear, vibration, and chafing.

These clamps combine a metal core for strength with a rubber or vinyl lining that cushions the component it holds, making them essential in automotive, specialty vehicle, and industrial manufacturing applications.

Types and Uses

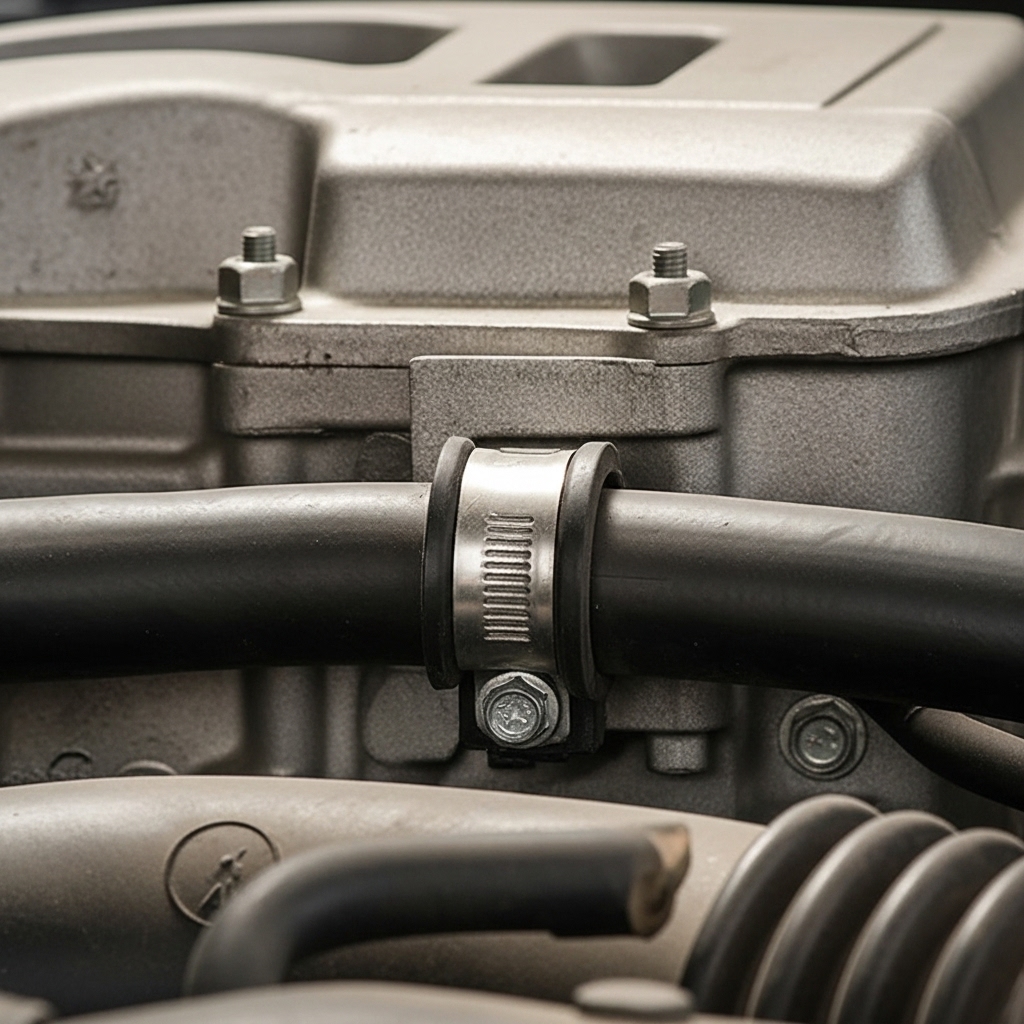

- Rubber Clamps: Metal clamps with a rubber lining that protect hoses or cables from abrasion. Ideal for areas with vibration or where hoses contact metal surfaces.

- Insulated Clamps: Similar to rubber clamps, these clamps often include additional insulation to prevent electrical shorts when securing wiring harnesses.

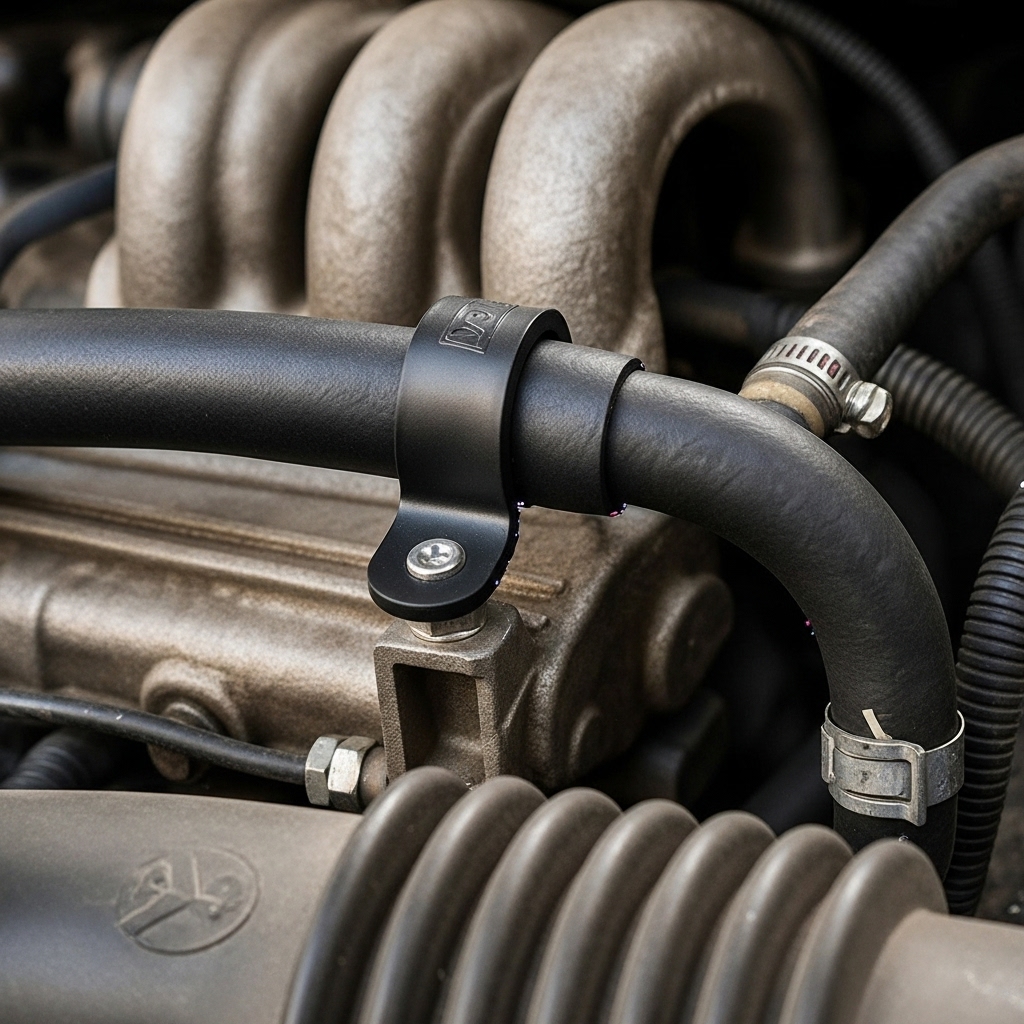

- Cushioned P-Clamps (Nylon Clamps): Shaped like a “P,” these clamps route or secure harnesses and cables under hoods or along a chassis.

Example Applications

- Automotive & Specialty Vehicles: For securing fuel lines, wiring harnesses, and brake hoses.

- Industrial Machinery: For organizing cables and hydraulic lines while preventing wear.

- Heavy Equipment & Outdoor Use: For protecting hoses and lines from vibration, impact, and abrasion in demanding environments.

From the Ram Products Experts

“Rubber clamps or cushioned P-clamps (nylon clamps) extend the life of your components, especially in areas prone to vibration. They absorb shocks that a standard metal clamp can’t, keeping lines and wiring intact longer.”

Explore Ram’s Coated and Insulated Metal Clamps to see the full range of sizes and materials designed for long-lasting protection.

Choosing the Right Clamp for the Job

With so many clamp types available, choosing the right one can feel overwhelming. The key is to focus on your application first: what you’re securing, the environment, and the level of protection required.

Project Factors to Consider

Application Type:

- Fluid Lines: Hose clamps like worm gear or T-bolt provide a tight, leak-free seal.

- Routing Hoses or Cables: Rubber-coated or cushioned P-clamps (nylon clamps) protect components from abrasion and vibration.

Pressure & Load:

High-pressure hoses, such as turbocharger lines, often require T-bolt or heavy-duty clamps to maintain consistent force.

Environment:

Exposure to heat, chemicals, UV, or moisture affects clamp longevity. Stainless steel resists corrosion, while rubber or vinyl liners provide insulation and cushioning.

Material & Size:

Choose the right diameter and clamp material to match the hose or cable. Undersized clamps can damage hoses; oversized clamps may slip or fail.

Maintenance Considerations:

In applications with frequent inspections or replacements, reusable clamps may save time and labor.

By taking the time to consider these factors, you can select the right clamp for long-lasting performance, safety, and efficiency.

Common Mistakes & Misuse

Even experienced technicians can make mistakes when selecting or installing clamps. Misuse often leads to leaks, cable wear, or unnecessary downtime. Understanding the most frequent errors can help you avoid costly problems.

Typical Clamp Mishaps

- Wrong Clamp for the Job: Using a hose clamp on a wiring bundle, or a P-clamp (nylon clamp) on a high-pressure hose, can cause wear, vibration damage, or leaks.

- Incorrect Sizing: Clamps that are too tight can damage hoses, while clamps that are too loose may allow movement or leaks.

- Poor Placement or Spacing: Placing clamps too far apart can let hoses sag or vibrate, increasing wear points.

- Material Mismatch: Carbon steel in corrosive environments or outdoors can rust quickly; always consider stainless steel or coated options for durability.

- Ignoring Installation Prep: Installing clamps over dirty or oily surfaces reduces grip and can lead to slippage or early failure.

From the Ram Products Experts

“Remember that P-clamps are made of nylon. Don’t use them on the outside of a vehicle where they are exposed to direct sunlight and subject to extreme weather and temperature changes.”

Recognizing these common mistakes allows you to make smarter choices, extend component life, and keep operations running smoothly.

Key Installation Tips

- Measure Before Installing: Always confirm the hose or cable diameter matches the clamp size. A snug, correctly sized clamp prevents slippage without damaging the component.

- Avoid Over-Tightening: For worm-gear or T-bolt clamps, excessive torque can cut into hoses or deform lines. Tighten just enough to secure the hose or cable.

- Align Cushioned Clamps Properly: Cushioned clamps should sit evenly around the hose or cable to distribute pressure and prevent localized wear.

- Even Spacing: Long runs of hoses or cables should have clamps spaced evenly to prevent sagging, rubbing, or vibration damage.

- Routine Checks: Inspect clamps periodically, especially in high-vibration or high-heat environments, and retighten if necessary.

Installation Best Practices

Even the best clamp won’t perform well if it’s installed incorrectly. Proper installation ensures that hoses, cables, and lines stay secure while avoiding damage or premature wear.

From the Ram Products Experts

“Space your clamps close enough so that whatever they’re securing won’t sag or move. This keeps hoses or wires from rubbing against anything and causing failure.”

Following these best practices ensures clamps perform their job reliably, protecting your hoses, cables, and overall equipment investment.

Clamp Selections at Ram Products

Selecting the right clamp can make a big difference in the performance and longevity of your work. Ram Products carries a wide variety of rubber clamps and other clamp types to meet the needs of automotive shops, industrial manufacturers, and specialty vehicle upfitters.

Ram Products’ Clamp Offerings

- Hose Clamps: From worm gear and T-bolt to ear and spring clamps, Ram has the right clamp for virtually any fluid-line application. Durable materials and a range of sizes ensure a secure, leak-free fit.

- Rubber Clamps & Insulated Clamps: Protect hoses and cables from abrasion, vibration, and electrical shorts. Available in multiple sizes and materials, including rubber cushioned clamps for added protection.

- Material Options: Stainless steel, carbon steel, and coated finishes provide corrosion resistance for indoor or outdoor applications.

Get Expert Support from the Ram Products Team

We offer a wide selection of rubber clamps and hose clamps to fit every application, along with expert guidance to help you make the right choice for your shop or facility.

Looking for pricing or personalized guidance? Create an account or contact our team today.